Conclusion and Current State of the Art

Wednesday, February 6th, 2008.

The port to C/C++ has exposed some bugs in the original program, greatly improved performance, incorporated the new equipment, and opened the doors to anyone that wants to develop their own platform without having to be an expert in Matlab. I have developed a JAVA GUI, although there is still room for more improvement.

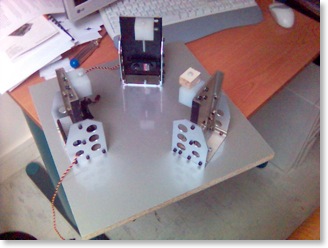

The new table the the UL is very exciting, as it incorporates three axis control and a surface large enough that the non-holonomic trajectories should finally be able to be explored.

Sun., September 18th, 2005.

The project has advanced quite far, although there's still much further to go. Among my objectives, I actually haven't attained very many of them. While it is true that the table stabilizes the ball, and can tell it to go anywhere on the table, the simple truth is that my trajectory planning isn't very good. This isn't exactly fantastic, and is far from the original goals of sending the ball careening around the corners.

Much of this delay has been because of my choice of materials. The legos were fun, and a necessary evil, but I simply didn't have enough of them to risk gluing them together permanently. This was a major error, both in time and frustration, because each time I wanted to do an experiment and things didn't proceed exactly as planned the table tended to break itself, requiring an intervention. This caused untold delays as half of my time was spent rebuilding what I'd already done.

I'm convinced that with another two weeks of work I can get the ball to follow a trajectory at reasonably low speeds, especially considering that the new table gave me some ideas to upgrade the old one. My experiments last night showed that my modifications have already greatly improved the reliability of my lego table, and I'm kicking myself for not having thought of them earlier.